Ultrasonic insertionCompression limiters are placed into a molded or drilled hole that is slightly smaller than the diameter of the insert. Danielson CT SPIROL recently released their new Compression Limiter Design Guide that provides essential design guidelines for the ideal bolted joint in plastic assemblies.

The load causes compression which can lead to.

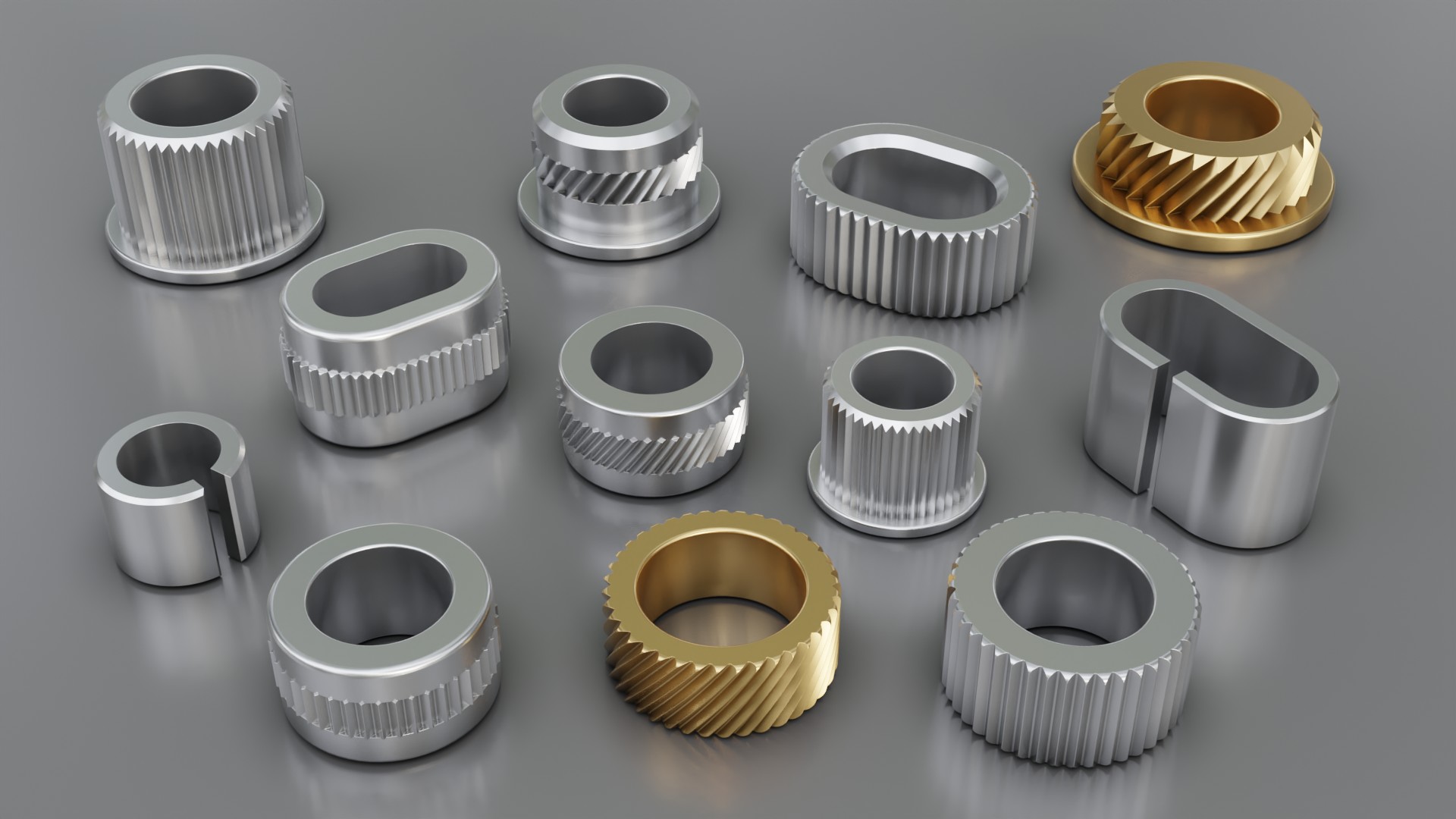

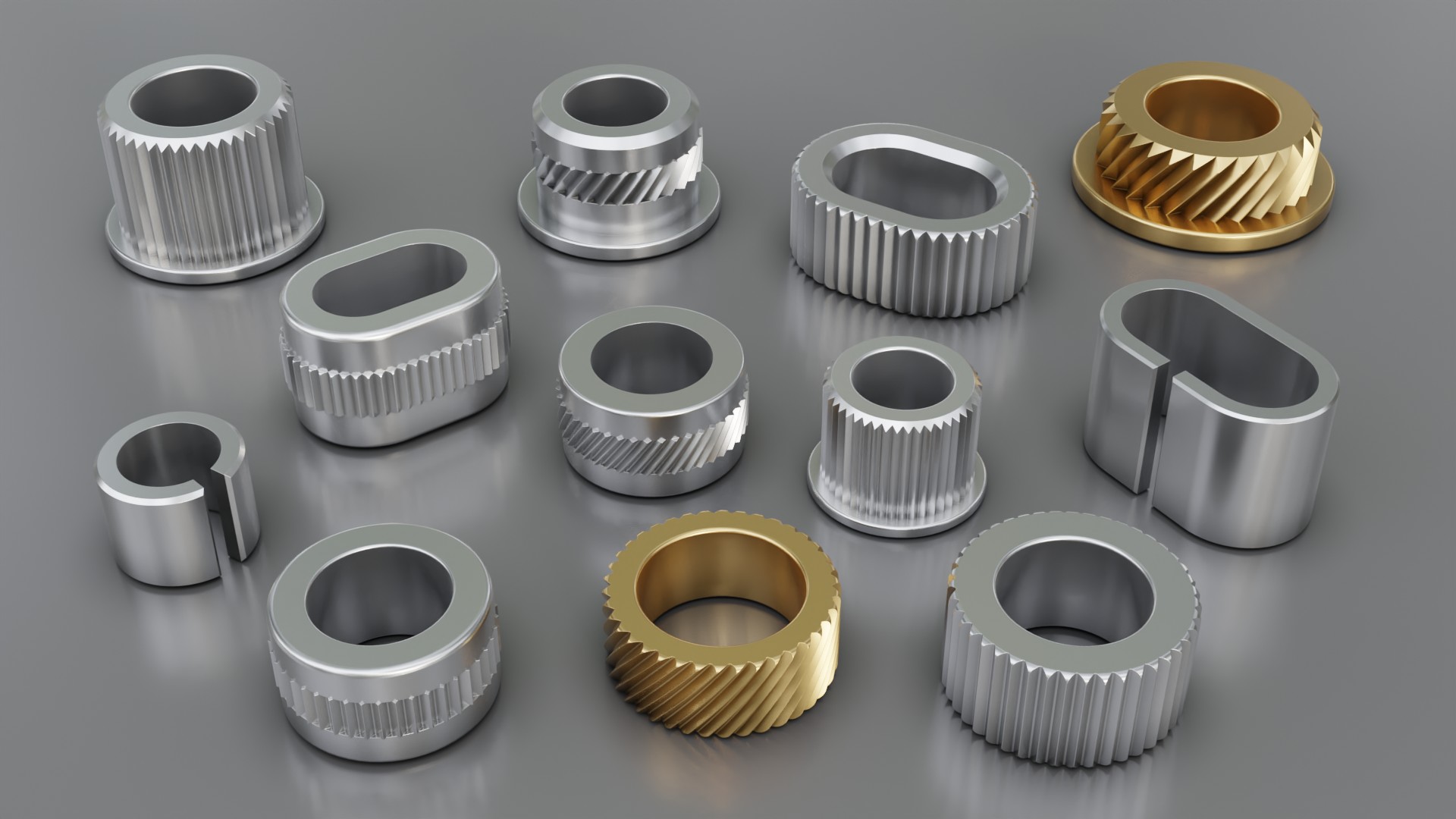

. Compression Limiters Dodgenon-threaded bushings expand the Dodge offering and are custom designed for your specific application. The length of the Compression Limiter. SPIROL recently released their new Compression Limiter Design Guide that provides essential design guidelines for the ideal bolted joint in plastic assemblies.

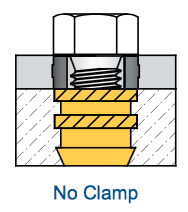

2 SPIROLs 5 Step Process for Success When you engage SPIROL as part of your team we will utilize our. The compression limiter strengthens the plastic component and withstands the compressive force that is applied when a mating screw is tightened. 1 COMPRESSION LIMITERS π x Ø2 2 - Ø1 2 ØA ØC ØB L 2.

The appropriate length and length. SPIROL offers standard installation equipment for post-mold Compression Limiter. Open the catalog to page 9 SPLIT SEAM.

To compress the Limiter 25 of its nominal length to the clamp load of the nominal sized fastener. Compression Limiters are rated by the load required to compress the. Testing facilities are available and testing and a report of the results is a free service provided to our customers.

SPIROL Compression Limiters Design Guide 1. Experience in the field of Insert design and application. The following design guidelines should be considered when a Compression Limiter is used to ensure its effectiveness in the plastic assembly.

The Compression Limiter will absorb additional clamping loads without further. The solution Compression limiters are non-threaded inserts designed to protect plastic parts from loads created by the tightening of bolts. The CL801 headed brass Compression Limiters are the same as the CL800 with the addition of a head.

Download Compression Limiters - Series CL600 - Knurled - Aluminum - Metric Sizes. Danielson CT SPIROL recently released their new Compression Limiter Design Guide that provides essential design guidelines for the ideal bolted joint in plastic assemblies. Available for SOLIDWORKS Inventor Creo CATIA Solid Edge autoCAD Revit and many more CAD software.

The following design guidelines should be considered when a Compression Limiter is used to ensure its effectiveness in the plastic assembly. Ultrasonic energy is applied to the compression limiter. Compression Limiters are metal inserts designed to protect molded plastic components from the compressive loads generated by the tightening of bolts or screws.

Thereafter the Compression Limiter and plastic will compress at the same although greatly reduced rate. The Limiters can be pressed in or installed with either. Compression limiters are non-threaded bushings that strengthen the plastic and resist the applied compressive loads.

Plas Fix 45 Installation Guide. The integrity of the plastic component. A properly designed bolted joint must meet the following criteria.

The Compression Limiters length should be designed to ensure it will bottom out against the surface under the bolts head and mating component. The head of the bolt or washer if one is used should always seat against the Compression Limiter under load. COMPRESSION LIMITERS x 22 - 12 AP 4 B L A C 1 The Function of a Compression Limiter The primary function of a Compression Limiter is to provide and maintain joint integrity of a.

It is imperative that the proper Compression Limiter be. Screws for Plastic to JIS. The Compression Limiters length should be designed to ensure it will bottom out against the surface under the bolts head and mating component.

ØA ØC ØB L π x Ø2 2 - Ø1 2 AP 4 COMPRESSION LIMITERS 2.

How To Ensure Bolted Joint Integrity When Using A Compression Limiter In A Plastic Assembly Medical Design And Outsourcing

Compression Limiters Launched Engineer Live

How To Ensure Bolted Joint Integrity When Using A Compression Limiter In A Plastic Assembly 2015 11 04 Assembly Magazine Assembly

How To Ensure Bolted Joint Integrity When Using A Compression Limiter In A Plastic Assembly Fastener Fixing Magazine

0 comments

Post a Comment